| Availability: | |

|---|---|

| Quantity: | |

FR

HKR

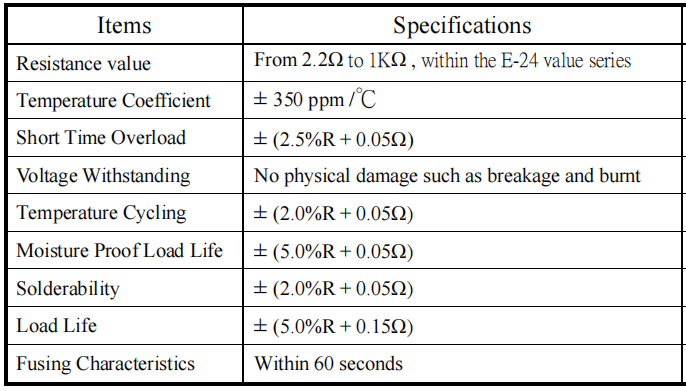

Fusible metal film resistor charactoristics:

Temperature Coefficient:

Take down the resistance value at the ambient temperature (25℃) and the value after the test taken at the temperature of higher than 100℃ for about 30-40 minutes, the readings will be used with the following formula to get the T.C. of ±350 PPM/℃.

T.C(PPM/℃) =(R - R0) / R0 × 1/(T - T0)

where T0 : ambient temperature of 25℃

T : test temperature of about 125℃

R0: resistance value at ambient temperature of 25℃

R : resistance value at test temperature of 125℃

Moisture-proof Load Life:

The resistors are put into a constant temperature/ humidity oven where the temperature is 40±2℃ and the relative humidity is 90~95% with the related voltage (not exceeding the maximum working voltage) for 90 minutes and then draw the resistors back to the normal room temperature for 30 minutes-take this as a test cycle. Repeat this test cycle for 500 or 1,000 hours. Leave the tested pieces back to a room temperature for about 60 minutes after the test cycle, take the readings of the resistance value change between pre-and post-test, the change rate is about ±(5.0%R±0.05Ω).

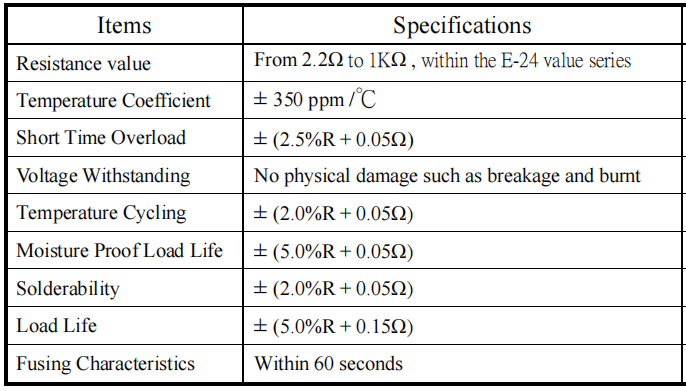

Fusible metal film resistor charactoristics:

Temperature Coefficient:

Take down the resistance value at the ambient temperature (25℃) and the value after the test taken at the temperature of higher than 100℃ for about 30-40 minutes, the readings will be used with the following formula to get the T.C. of ±350 PPM/℃.

T.C(PPM/℃) =(R - R0) / R0 × 1/(T - T0)

where T0 : ambient temperature of 25℃

T : test temperature of about 125℃

R0: resistance value at ambient temperature of 25℃

R : resistance value at test temperature of 125℃

Moisture-proof Load Life:

The resistors are put into a constant temperature/ humidity oven where the temperature is 40±2℃ and the relative humidity is 90~95% with the related voltage (not exceeding the maximum working voltage) for 90 minutes and then draw the resistors back to the normal room temperature for 30 minutes-take this as a test cycle. Repeat this test cycle for 500 or 1,000 hours. Leave the tested pieces back to a room temperature for about 60 minutes after the test cycle, take the readings of the resistance value change between pre-and post-test, the change rate is about ±(5.0%R±0.05Ω).